Vise Grip T Slot Clamp

Vise-Grip The Original Locking C-Clamps with Regular TIps, 9 in. Vise-Grip 5-Piece Welding Clamp Kit with T-Shirt. Vise-Grip 2-Piece Adjustable Wrench Set 6 in. Serrated Pivoting Jaws Similar to locking pliers, the jaws lock in a vise-like grip. Turn the adjustment knob to change the opening size; squeeze the handles to lock the jaws. Clamps with pull-open lock release open when you pull down on the bottom handle. 12 PCS CLAMP KIT FOR BRIDGEPORT MILL with 5/8' T-slot Low Profile Cam Action 202-4799. Positive side gripping action provides greater strength No. More loose parts to reassemble, If one of the six sides is worn or damaged just turn to another. Half turn provides.100' movement, 4 T-nuts. Check out our vise grip with clamp selection for the very best in unique or custom, handmade pieces from our shops. Screw-Mount Toe Clamps; Sine Plate & Magnetic Chuck Combination; Sine Plates; Sliding Machining Tables; T-Slot Toe Clamps; Tombstones & Plates; Vise; Vise Accessories; Vise Jaws; Wedge Clamps; Shop All; Pitbull Clamp. Low profile and high grip from Mitee-Bite. Shop Now; Measuring. Angle Blocks & Sets; Bench Centers; Bore Gages.

Steel is strong. Much stronger than wood, in fact. However, I think it’s interesting to see how well wood can work for tools that are typically made from steel. Usually if you can make the parts big enough that will close that strength gap, somewhat. But then that added size can make the tool too bulky and unusable. Impractical, in other words.

Take the vise grip clamp, for example. I’ve seen toggle clamps made from wood that seem to work well, and they operate on the same principle. Of course, the wooden versions almost certainly don’t work as well as the steel versions, but might work well enough to be used reliably. And that’s the key: reliability, not ultimate strength.

As is the case for most of my projects that have moving parts, I made a mock up. Two, in fact, and this is the first, less refined version:

Made quickly from lower quality plywood just to get a read on how well the locking mechanism works and how critical the alignment is. Most people take a lot for granted just looking at tools like this, not realizing how much design and trial and error went into it.

I spent some time refining the design in SketchUp and that’s what I used to build the second version. I posted a picture of that one on Instagram right after I made it:

Months pass, as they often do, before I get back to this project. I used the original SketchUp drawing to make a quick template sheet for the parts with the idea that I would refine the design while building:

And refine I did. I made a new template sheet that you can print to make one (or a dozen) of these for yourself. Just right click the image an select “save image as” and save it to a convenient location. To print, use standard letter size paper (11 x 8.5) and set the print to fullsize or no scaling.

Note the extend 1-1/8″ – that part was too long for the sheet, so cut it out that much longer on that end.

I used scraps of 1/2″ and 3/4″ Baltic birch plywood to make mine. Plywood is recommended, since it has strength in all directions. I used a glue stick to paste on the parts cut roughly from the template:

Then carefully cut them out on my band saw. I used my router table to cut the 3/8″ slots in these parts:

All of the parts cut out, sanded and the pivot dowels glued in. The video at the bottom of this page shows more details on making the parts:

A quick dry fit to see how everything lines up:

A part not detailed on the template sheet is the block for the adjuster. It’s made from 3/4″ plywood and has a 3/8″ nut glued into a counterbore:

Again, more detail in the video.

Vise Grip T Slot Clamps

With the clamp assembled, I did a nice job of rounding the edges and sanding it smooth to make it more comfortable to use:

And then put on two coats of water based polyurethane. Much, much better to do that before the clamp is assembled, though:

Here it is in action, clamping a glue joint:

Now, obviously this does not have the same clamping force as a metal version. But it does have enough to be useful for a great many things in the hobbyist shop. An improvement that I want to do with mine is to add swiveling pads to the jaws. That will increase the surface area and make this very handy for clamping two surfaces flush.

And while this is a useful clamp, building it can serve another purpose: it will hone your skills when working with projects with moving parts, and it can also make you appreciate the design and build time that goes into these types of tools.

Oh and it looks cool, too!

Here’s the full build video:

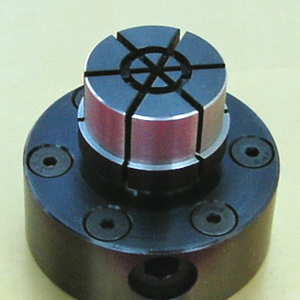

KURT 5-AXIS WORKHOLDING

Introducing new Precision Force MaxLock™ vises. Available now for preorder and August delivery.

KURT WORKHOLDING SOLUTIONS

Holding your products — and our competitors’ attention — since 1959.

KURT AUTOMATION SOLUTIONS

Excellence is automatic. Our automated processes increase speed, accuracy, and employee satisfaction.

KURT CUSTOM WORKHOLDING SOLUTIONS

Our custom vises are designed to work for you — and only you.

KURT GAGING SOLUTIONS

Precision is everything. Kurt gaging solutions keep you focused on delivering perfection.

KURT TOWERS

Kurt vises and towers grip so tight, they even hold our competitors’ attention.

PRECISION BY DESIGN.

PERFECT BY DESIRE.

When you demand quality, Kurt delivers every time. Kurt vises sets the standard in reliability for CNC machining or precision workholding requirements. No other company comes close to the variety, dependability, or precision of Kurt vises. And it shows.

Vise Grip Clamp Set

The original Kurt AngLock® vises were designed to provide precision part clamping for basic machining and milling applications. Our line of Kurt vises includes high precision CNC vises, 5-axis vises, rotary table workholding solutions for VMCs, and ToolBlox tombstones. Our precision workholding solutions provide increased versatility at your CNC machining stations. Precision measuring systems and accessories are also available to complement your Kurt workholding system.